2022 High quality Solid Steel Sphere - 316 stainless steel balls high quality precision – Mingzhu

2022 High quality Solid Steel Sphere - 316 stainless steel balls high quality precision – Mingzhu Detail:

316 stainless steel balls are similar to the AISI 304 stainless Steel ball, it has a better resistance to the corrosion under particular circumstances and this is mainly due to the addition of molybdenum. At first studied to resist to the corrosion of compounds with sulfuric acid, it is now primarily used for application in paper-industry, in food industry and for other process of industrial chemistry, concerning its general resistance to acids, barring the hydrochloric one. The AISI 316 Steel is certainly more magnetic than the AISI 304 one. The AISI 316 stainless steel, universally considered non magnetic.

Specification

|

316 stainless steel balls |

|

|

Diameters |

2.0mm – 55.0mm |

|

Grade |

G100-G1000 |

|

Application |

pumps and valves, aerosol and dispenser sprayers, utensil in the foodstuff, paper, chemical, rubber, military, textile industry. Applications in photographic devices, medical instruments, quick couplings, recirculating balls, ink cartridges, jewels. |

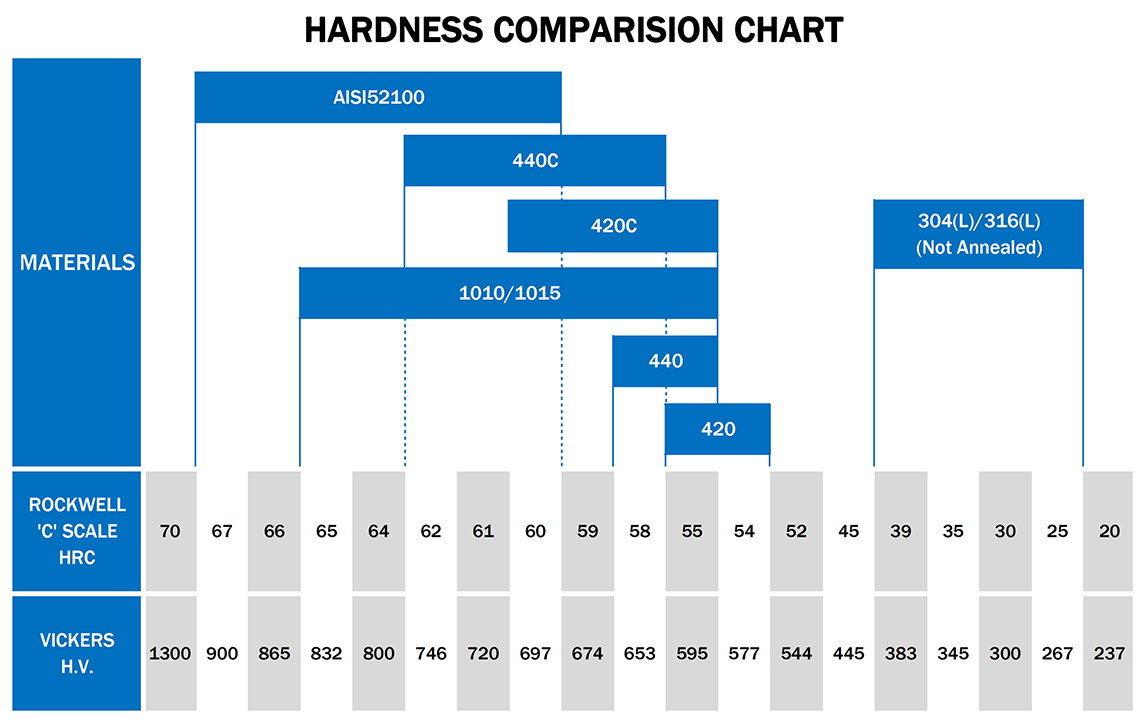

Hardness

|

316 stainless steel balls |

|||

|

According to DIN 5401:2002-08 |

According to ANSI/ABMA Std. 10A-2001 |

||

|

over |

up to |

|

|

|

all |

all |

27/39 HRC |

25/39 HRC. |

Equivalence Of Material

|

316 stainless steel balls |

|

|

AISI/ASTM(USA) |

316 |

|

VDEh (GER) |

1.4401 |

|

JIS (JAP) |

SUS316 |

|

BS (UK) |

316 S 16 |

|

NF (France) |

Z6CND17.11 |

|

ГОСТ(Russia) |

08KH16N11M3 |

|

GB (China) |

0Cr17Ni12Mo2 |

Chemical Composition

|

316 stainless steel balls |

|

|

C |

≤0.07% |

|

Si |

≤1.00% |

|

Mn |

≤2.00% |

|

P |

≤0.045% |

|

S |

≤0.03% |

|

Cr |

16.50% - 18.50% |

|

Mo |

2.00% - 2.50% |

|

Ni |

10.00% - 13.00% |

|

N |

≤0.11% |

Corrosion Resistance Chart

| CORROSION RESISTANCE CHART | ||||||||||

| MATERIAL | Industrial atmospheres | Salt air | WATER | FOOD | LIQUOR | |||||

| Wet steam | Domestic water | Sea water | Food products | Fruit & veg. juice | Dairy products | Hot sulfite | Dye | |||

| 52100 Chrome Steel | C | / | D | D | / | / | / | / | / | / |

| 1010/1015 Carbon Steel | D | / | / | / | / | / | / | / | / | / |

| 420(C)/440(C) stainless Steel | B | C | B | B | / | B | B | C | / | D |

| 304(L) stainless Steel | B | A | A | A | A | A | B | A | A | D |

| 316(L) stainless Steel | B | A | A | A | A | A | A | A | B | D |

| A = Excelent B = Good C = Fair D = Poor / = Not suitable | ||||||||||

Our Advantage

● We have been engaged in steel ball production for more than 26 years;

● We offer a great variety of sizes ranged from 3.175mm to 38.1mm. Non-standard sizes and gauges can be manufactured under special request (such as 5.1mm, 5.15mm, 5.2mm, 5.3mm 5.4mm for seat track; 14.0mm for cam shaft and CV joint, etc.);

● We have a wide stock availability. Most of the standard sizes (3.175mm~38.1mm) and gauges (-8~+8) are available, which can be delivered immediately;

● Each batch of balls is inspected by sophisticated machines: roundness tester, roughness tester, metallographic analysis microscope, hardness tester (HRC and HV) to guarantee the quality.

FAQ

Q: How do I choose the appropriate stainless steel brand (304(L)/316(L)/420(C)/440(C))? What are the main differences between 300 and 400 series stainless steel balls?

A: To choose the proper steel brand for stainless steel balls, we should get to know well the properties of each brand and the application of the balls. The most common used stainless steel balls can be divided simply in two groups: 300 series and 400 series.

300 series “austenitic” stainless steel balls contain more chromium and nickel elements and are theoretically non-magnetic (actually are very low-magnetic. Totally non-magnetic require additionally heat treated.). Normally they are produced without the heat treatment process. They have better corrosion resistance than 400 series (in fact, the highest corrosion resistance of the stainless group. Although 300 series balls are all quite resistant, however 316 and 304 balls show different resistance to some substance. For more details, please refer to pages of different stainless steel balls) . They are less brittle, so can be applied also for sealing use. 400 series stainless steel balls contain more carbon, which makes it magnetic and more hardness. They can be easily heat treated like chrome steel balls or carbon steel balls to increase hardness. 400 series stainless steel balls are commonly used for applications that demand water-resistance, strength, hardness and wear resistance.

Q: How is your quality assurance?

A: All produced balls are 100% sorted by the sorting bar and checked by the photoelectric surface defect detector. Before packaging samples balls from the lot are to send for final inspection to check for the roughness, roundness, hardness, variation, crush load and vibration in compliance with the standard. If all requirements are met, a inspection report will be made for the customer. Our sophisticated laboratory is equipped with high precision machines and equipment: Rockwell hardness tester, Vickers hardness tester, crushing load machine, roughness meter, roundness meter, diameter comparator, metallographic microscope, vibration measuring instrument, etc..

Q: We are not familiar with the international transportation. Will you handle all logistics?

A: Definitely, we deal with the logistic issues with our cooperated international freight forwarders with years’ of experience. The customers only need to provide us the basic information

Q: How is your packaging method?

A: 1. Conventional packaging method: 4 Inner boxes (14.5cm*9.5cm*8cm) per master carton (30cm*20cm*17cm) with dry plastic bag with VCI anti-rust paper or oiled plastic bag, 24 cartons per wooden pallet (80cm*60cm*65cm). Each carton weighs roughly 23kgs;

2.Steel drum packaging method: 4 steel drums (∅35cm*55cm) with dry plastic bag with VCI anti-rust paper or oiled plastic bag,4 drums per wooden pallet (74cm*74cm*55cm);

3.Customized packaging as per customer’s requirement.

Product detail pictures:

Related Product Guide:

We not only will try our to offer excellent services to every customer, but also are ready to receive any suggestion offered by our customers for 2022 High quality Solid Steel Sphere - 316 stainless steel balls high quality precision – Mingzhu , The product will supply to all over the world, such as: Berlin, Iraq, Morocco, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a must for yourself personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We have been confident that we will have a vibrant prospect and to be distributed all over the world in the years to come.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top