Original Factory 2 Inch Steel Ball - 304 stainless steel balls high quality precision – Mingzhu

Original Factory 2 Inch Steel Ball - 304 stainless steel balls high quality precision – Mingzhu Detail:

304 stainless steel balls are resistant to corrosion of oxidative solution, particularly to those produced by chemical component of organic nature, they are resistant to water, sea-air, and organic acids. However they are not very resistant to the attacks of and sulfuric acids. Therefore they are suitable for valves and relevant applications with resistance to corrosion plays an important role, whilst is a secondary factor. This stainless steel, universally considered non magnetic.

Specification

|

304 stainless steel balls |

|

|

Diameters |

2.0mm – 55.0mm |

|

Grade |

G100-G1000 |

|

Application |

pumps and valves, aerosol and dispenser sprayers, miniature pumps, utensil in the foodstuff, medical application valves, agricultural backpack sprayers. |

Hardness

|

304 stainless steel balls |

|||

|

According to DIN 5401:2002-08 |

According to ANSI/ABMA Std. 10A-2001 |

||

|

over |

up to |

|

|

|

- |

70 |

280/380HV10 27/39 HRC |

25/39 HRC. |

Equivalence Of Material

|

304 stainless steel balls |

|

|

AISI/ASTM(USA) |

304 |

|

VDEh (GER) |

1.4301 |

|

JIS (JAP) |

SUS304 |

|

BS (UK) |

304 S 15 |

|

NF (France) |

Z7CN18-09 |

|

ГОСТ(Russia) |

08KH18N10 |

|

GB (China) |

0Cr18Ni9 |

Chemical Composition

|

304 stainless steel balls |

|

|

C |

≤0.08% |

|

Si |

≤0.75% |

|

Mn |

≤2.00% |

|

P |

≤0.045% |

|

S |

≤0.03% |

|

Cr |

18.00% - 20.00% |

|

Ni |

8.00% - 10.50% |

|

N |

≤0.10% |

Our Advantage

● We have been engaged in steel ball production for more than 26 years;

● We offer a great variety of sizes ranged from 3.175mm to 38.1mm. The size spreadsheet can be referred as follows;

● We have a wide stock availability. Most of the standard sizes (3.175mm~38.1mm) and gauges (-8~+8) are available, which can be delivered immediately;

● Non-standard sizes and gauges can be manufactured under special request (such as 5.1mm, 5.15mm, 5.2mm, 5.3mm 5.4mm for seat track; 14.0mm for cam shaft and CV joint, etc.);

● Each batch of balls is inspected by sophisticated machines: roundness tester, roughness tester, metallographic analysis microscope, hardness tester (HRC and HV) to guarantee the quality.

Size Spreadsheet

|

SIZE SPREADSHEET |

|||

|

(mm) |

(inch) |

(mm) |

(inch) |

|

3.175 |

1/8″ |

8.7 |

- |

|

3.5 |

- |

8.731 |

11/32″ |

|

3.969 |

5/32″ |

9.0 |

- |

|

4.0 |

- |

9.525 |

3/8″ |

|

4.2 |

- |

10.0 |

- |

|

4.4 |

- |

10.3188 |

13/32″ |

|

4.5 |

- |

11.0 |

- |

|

4.63 |

- |

11.1125 |

7/16″ |

|

4.7 |

- |

11.5094 |

29/64″ |

|

4.7625 |

3/16″ |

11.9062 |

15/32″ |

|

4.8 |

- |

12.0 |

- |

|

4.9 |

- |

12.3031 |

31/64″ |

|

5.0 |

- |

12.7 |

1/2″ |

|

5.1 |

- |

13.0 |

- |

|

5.1594 |

- |

13.4938 |

17/32″ |

|

5.2 |

- |

14.0 |

- |

|

5.25 |

- |

14.2875 |

9/16″ |

|

5.3 |

- |

15.0812 |

19/32″ |

|

5.35 |

- |

15.0 |

- |

|

5.4 |

- |

15.875 |

5/8″ |

|

5.5 |

- |

16.0 |

- |

|

5.5562 |

7/32″ |

16.6688 |

21/32″ |

|

5.6 |

- |

17.4625 |

11/16″ |

|

5.9531 |

15/64″ |

19.05 |

3/4″ |

|

6.0 |

- |

20.0 |

- |

|

6.35 |

1/4″ |

20.637 |

13/16″ |

|

6.5 |

- |

22.0 |

- |

|

6.7469 |

17/64″ |

22.225 |

7/8″ |

|

7.0 |

- |

23.8125 |

15/16 |

|

7.1438 |

7/32″ |

25.4 |

1″ |

|

7.5 |

- |

30.1625 |

1 3/16″ |

|

7.62 |

- |

32.0 |

- |

|

7.9375 |

5/16″ |

38.1 |

1 1/2″ |

|

8.0 |

- |

|

|

FAQ

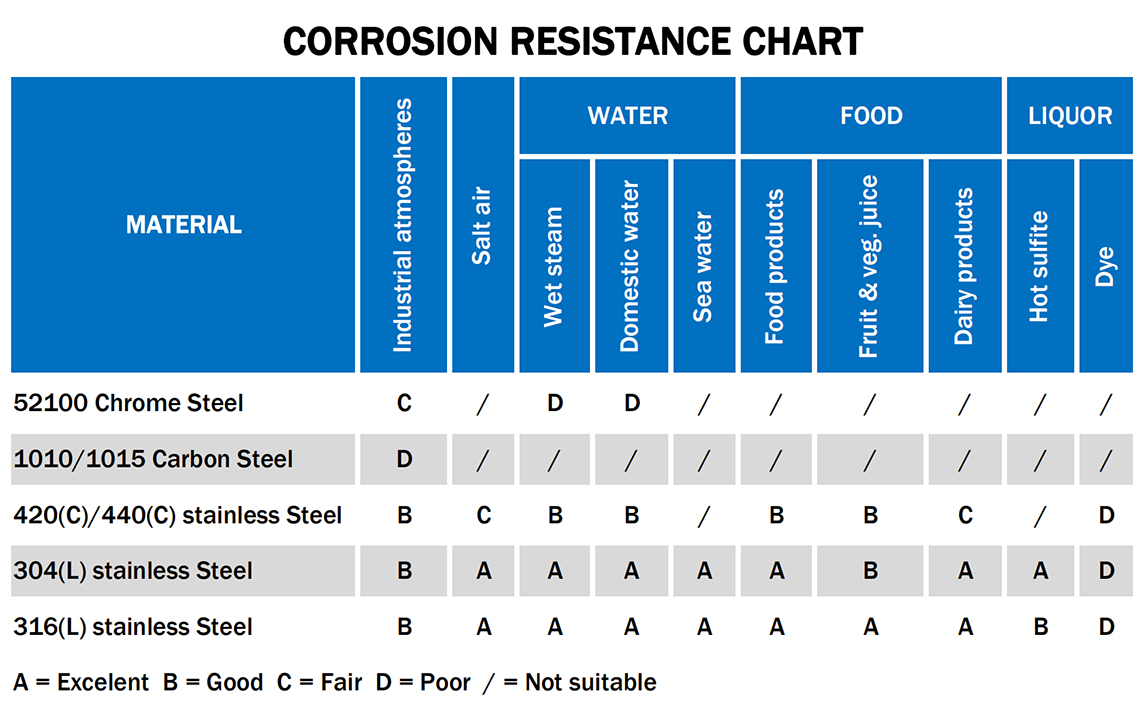

Q: How do I choose the appropriate stainless steel brand (304(L)/316(L)/420(C)/440(C))? What are the main differences between 300 and 400 series stainless steel balls?

A: To choose the proper steel brand for stainless steel balls, we should get to know well the properties of each brand and the application of the balls. The most common used stainless steel balls can be divided simply in two groups: 300 series and 400 series.

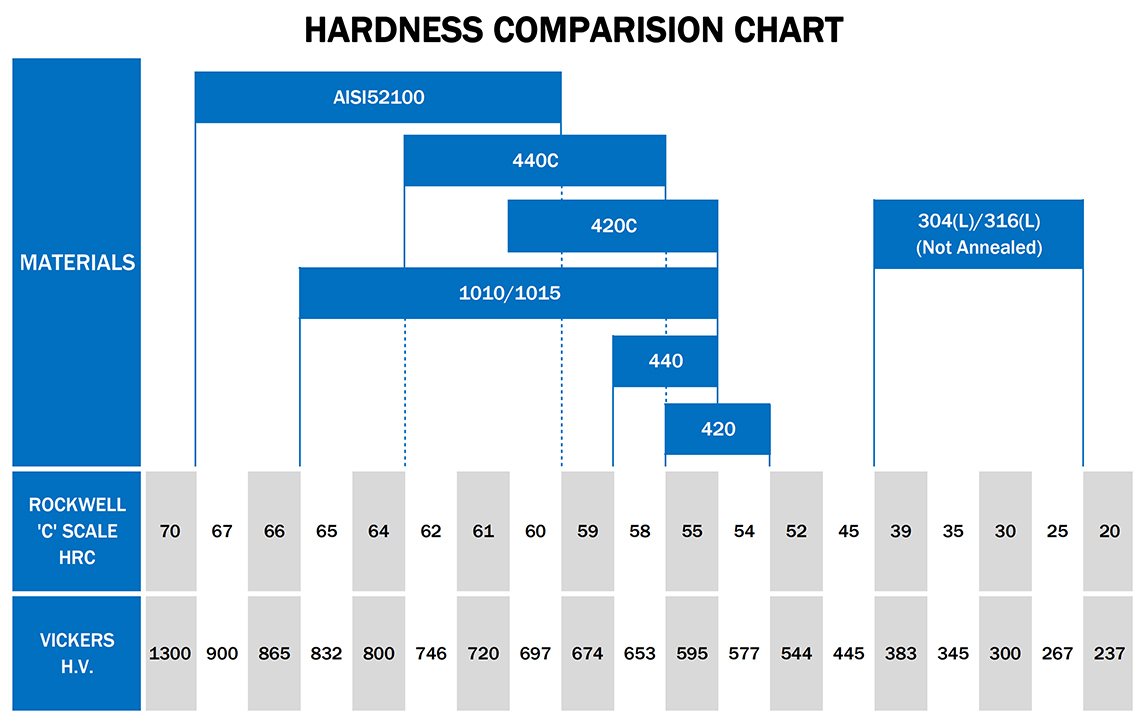

300 series “austenitic” stainless steel balls contain more chromium and nickel elements and are theoretically non-magnetic (actually are very low-magnetic. Totally non-magnetic require additionally heat treated.). Normally they are produced without the heat treatment process. They have better corrosion resistance than 400 series (in fact, the highest corrosion resistance of the stainless group. Although 300 series balls are all quite resistant, however 316 and 304 balls show different resistance to some substance. For more details, please refer to pages of different stainless steel balls) . They are less brittle, so can be applied also for sealing use. 400 series stainless steel balls contain more carbon, which makes it magnetic and more hardness. They can be easily heat treated like chrome steel balls or carbon steel balls to increase hardness. 400 series stainless steel balls are commonly used for applications that demand water-resistance, strength, hardness and wear resistance.

Q: What standards do you adhere to for manufacturing?

A: Our products are in compliance with the following standards industrial for steel balls:

● ISO 3290 (INTERNATIONAL)

● DIN 5401 (GER)

● AISI/ AFBMA (USA)

● JIS B1501 (JAP)

● GB/T308 (CHN)

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far reliable, trustable and honest provider, but also the partner for our customers for Original Factory 2 Inch Steel Ball - 304 stainless steel balls high quality precision – Mingzhu , The product will supply to all over the world, such as: Iran, Miami, Palestine, We've a skilled sales team, they have mastered high technological and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

Hope that the company could stick to the enterprise spirit of Quality, Efficiency, Innovation and Integrity, it will be better and better in the future.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top