Top Suppliers 1085 High Carbon Steel Balls - 1085 high carbon steel balls high quality precision – Mingzhu

Top Suppliers 1085 High Carbon Steel Balls - 1085 high carbon steel balls high quality precision – Mingzhu Detail:

1085 high carbon steel balls have a very good resistance to wear and stress because of the high C element percent. The hardness can reach from 59-66HRC. This kind of ball is commonly used in low precision bearings, bicycle, drawer slides, polishing medias and etc.

Specification

|

1018 carbon steel balls |

|

|

Diameters |

2.0mm – 55.0mm |

|

Grade |

G100-G1000 |

|

Hardness |

59/66 HRC |

|

Application |

casters, locks, drawer slides, bicycles, roller skates, slides, trolleys and conveyors. |

Equivalence Of Material

|

1015 carbon steel balls |

|

|

|

1085 |

|

AISI/ASTM(USA) |

1085 |

|

VDEh (GER) |

1.0616 |

|

JIS (JAP) |

SWRH87B |

|

BS (UK) |

C85S |

|

NF (France) |

XC90 |

|

ГОСТ(Russia) |

85 (A) |

|

GB (China) |

82B |

Chemical Composition

|

1085 carbon steel balls |

|

|

1015 |

|

|

C |

0.80% - 0.93% |

|

Si |

≤0.60% |

|

Mn |

0.70% - 1.00% |

|

P |

≤0.040% |

|

S |

≤0.050% |

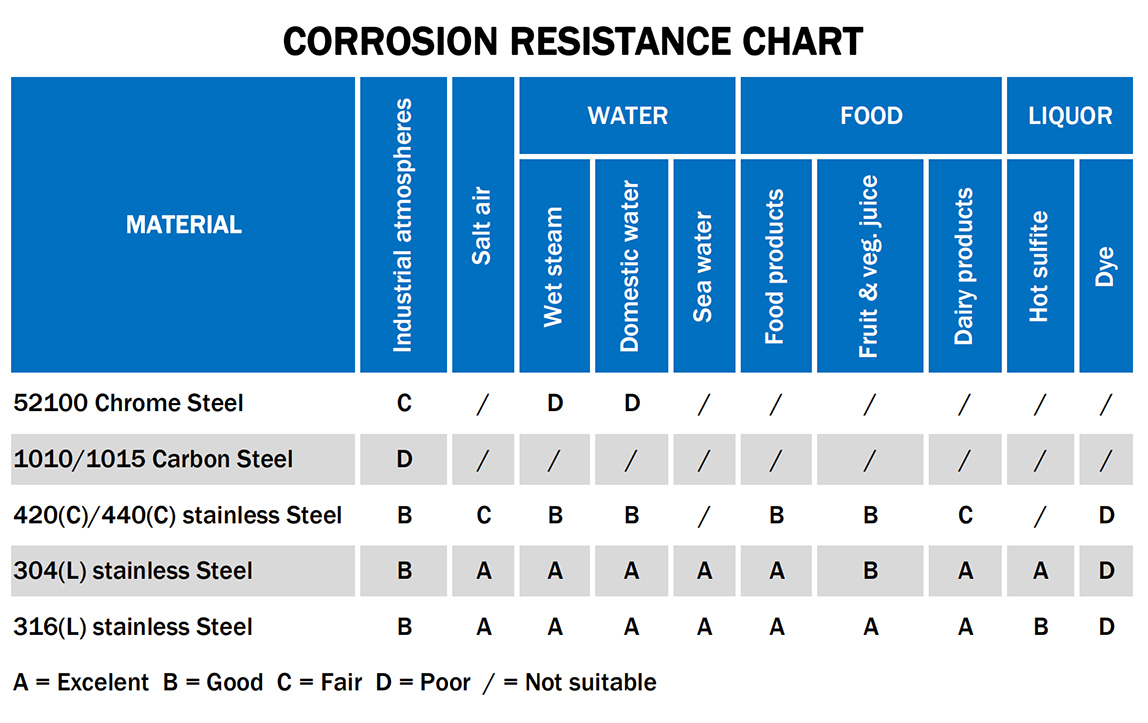

Corrosion Resistance Chart

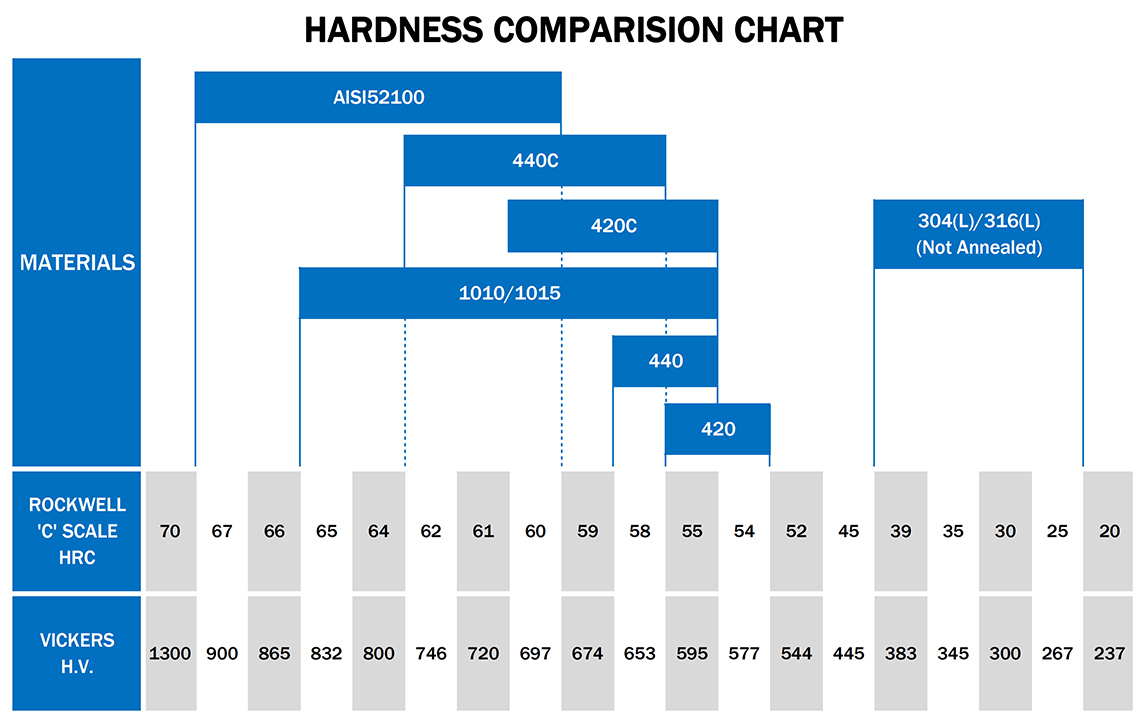

Hardness Comparision Chart

FAQ

Q: Do chrome steel balls perform better than carbon steel balls?

A: Chrome steel balls contain more alloy metals, which contribute toughness, hardness, resistant and are able to operate under heavy load, so are widely utilized in bearing and other industrial application. Carbon steel balls are only case-hardened. The interior part doesn’t achieve the same hardness as the surface. The application is drawer sliders, chair casters and toys.

Q: What standards do you adhere to for manufacturing?

A: Our products are in compliance with the following standards industrial for steel balls:

● ISO 3290 (INTERNATIONAL)

● DIN 5401 (GER)

● AISI/ AFBMA (USA)

● JIS B1501 (JAP)

● GB/T308 (CHN)

Q: Do you offer free samples for test?

A: Yes, we provide free samples to test and check quality.

Q: How long is your lead time?

A: Generally it takes around 3-5 days if the products are in stock. Or else the estimated lead time should be worked out according to your specific quantity, material and grade.

Q: We are not familiar with the international transportation. Will you handle all logistics?

A: Definitely, we deal with the logistic issues with our cooperated international freight forwarders with years’ of experience. The customers only need to provide us the basic information

Q: How is your packaging method?

A: 1. Conventional packaging method: 4 Inner boxes (14.5cm*9.5cm*8cm) per master carton (30cm*20cm*17cm) with dry plastic bag with VCI anti-rust paper or oiled plastic bag, 24 cartons per wooden pallet (80cm*60cm*65cm). Each carton weighs roughly 23kgs;

2.Steel drum packaging method: 4 steel drums (∅35cm*55cm) with dry plastic bag with VCI anti-rust paper or oiled plastic bag,4 drums per wooden pallet (74cm*74cm*55cm);

3.Customized packaging as per customer’s requirement.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science and the theory of quality the basic, belief the very first and management the advanced for Top Suppliers 1085 High Carbon Steel Balls - 1085 high carbon steel balls high quality precision – Mingzhu , The product will supply to all over the world, such as: Porto, Holland, Eindhoven, If any item be of interest to you, you should let us know. We will try our to satisfy your requirements with high quality goods, the lower prices and prompt delivery. You should feel free to contact us at any time. We will reply you when we receive your inquiries. Make sure you note that samples are available before we start our business.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top