Trending Products Large Stainless Steel Sphere - Low noise high precision steel balls – Mingzhu

Trending Products Large Stainless Steel Sphere - Low noise high precision steel balls – Mingzhu Detail:

Specification

|

Low noise high precision steel balls |

|

| Grade |

G5/G10 |

|

Material |

100Cr6, 440C |

|

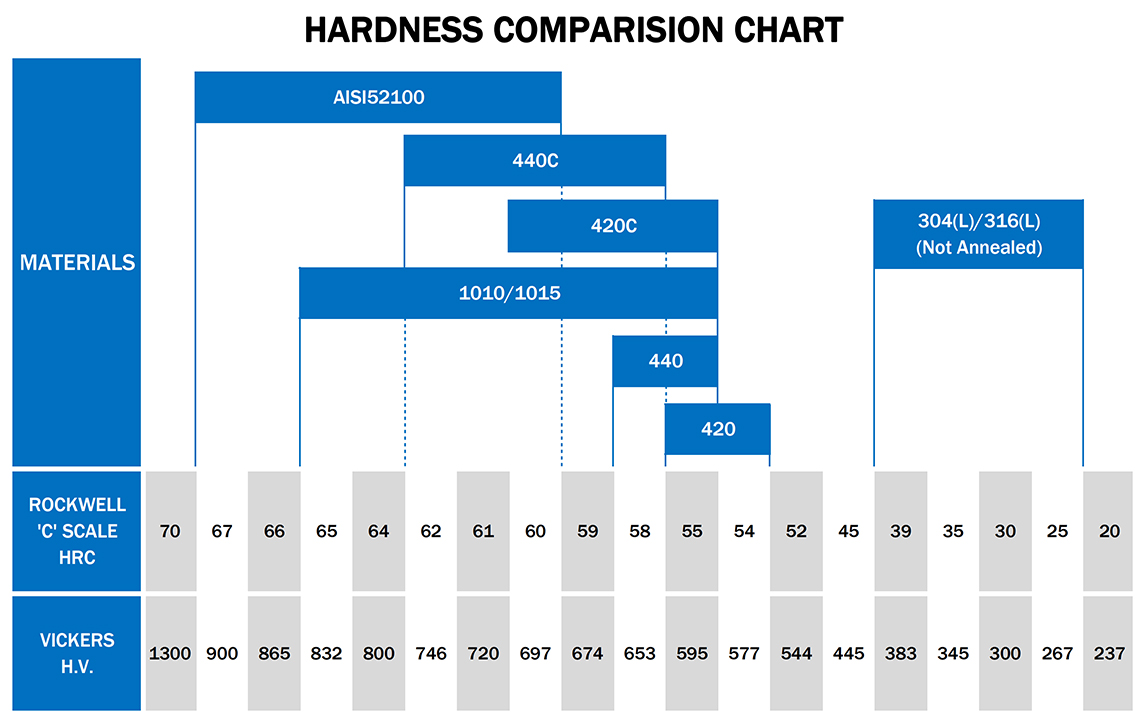

Hardness |

HRC 55-66 |

|

Certification |

ISO 9001, IATF 16949 qualified |

Diameter

|

SIZE SPREADSHEET |

|||

|

(mm) |

(inch) |

(mm) |

(inch) |

|

3.175 |

1/8″ |

8.7 |

- |

|

3.5 |

- |

8.731 |

11/32″ |

|

3.969 |

5/32″ |

9.0 |

- |

|

4.0 |

- |

9.525 |

3/8″ |

|

4.2 |

- |

10.0 |

- |

|

4.4 |

- |

10.3188 |

13/32″ |

|

4.5 |

- |

11.0 |

- |

|

4.63 |

- |

11.1125 |

7/16″ |

|

4.7 |

- |

11.5094 |

29/64″ |

|

4.7625 |

3/16″ |

11.9062 |

15/32″ |

|

4.8 |

- |

12.0 |

- |

|

4.9 |

- |

12.3031 |

31/64″ |

|

5.0 |

- |

12.7 |

1/2″ |

|

5.1 |

- |

13.0 |

- |

|

5.1594 |

- |

13.4938 |

17/32″ |

|

5.2 |

- |

14.0 |

- |

|

5.25 |

- |

14.2875 |

9/16″ |

|

5.3 |

- |

15.0812 |

19/32″ |

|

5.35 |

- |

15.0 |

- |

|

5.4 |

- |

15.875 |

5/8″ |

|

5.5 |

- |

16.0 |

- |

|

5.5562 |

7/32″ |

16.6688 |

21/32″ |

|

5.6 |

- |

17.4625 |

11/16″ |

|

5.9531 |

15/64″ |

19.05 |

3/4″ |

|

6.0 |

- |

20.0 |

- |

|

6.35 |

1/4″ |

20.637 |

13/16″ |

|

6.5 |

- |

22.0 |

- |

|

6.7469 |

17/64″ |

22.225 |

7/8″ |

|

7.0 |

- |

23.8125 |

15/16 |

|

7.1438 |

7/32″ |

25.4 |

1″ |

|

7.5 |

- |

30.1625 |

1 3/16″ |

|

7.62 |

- |

32.0 |

- |

|

7.9375 |

5/16″ |

38.1 |

1 1/2″ |

|

8.0 |

- |

||

Note: The diameters in the table above are the sizes we commonly manufacture. please contact us for unlisted sizes.

Our Advantage

● We have been engaged in steel ball production for more than 26 years;

● We offer a great variety of sizes ranged from 2.0mm to 55.0mm. The size spreadsheet can be referred as follows;

● We have a wide stock availability. Most of the standard sizes (2.0mm~55.0mm) and gauges (-8~+8) are available, which can be delivered immediately;

● Non-standard sizes and gauges can be manufactured under special request (such as 5.1mm, 5.15mm, 5.2mm, 5.3mm 5.4mm for seat track; 14.0mm for cam shaft and CV joint, etc.);

● Each batch of balls is inspected by sophisticated machines: roundness tester, roughness tester, metallographic analysis microscope, hardness tester (HRC and HV) to guarantee the quality.

FAQ

Q: What standards do you adhere to for manufacturing?

A: Our products are in compliance with the following standards industrial for steel balls:

● ISO 3290 (INTERNATIONAL)

● DIN 5401 (GER)

● AISI/ AFBMA (USA)

● JIS B1501 (JAP)

● GB/T308 (CHN)

Q: What kind of certificates do you achieve?

A: We own ISO9001:2008 management system certification and IATF16949: 2016 automotive industry quality management system certification.

Q: How is your quality assurance?

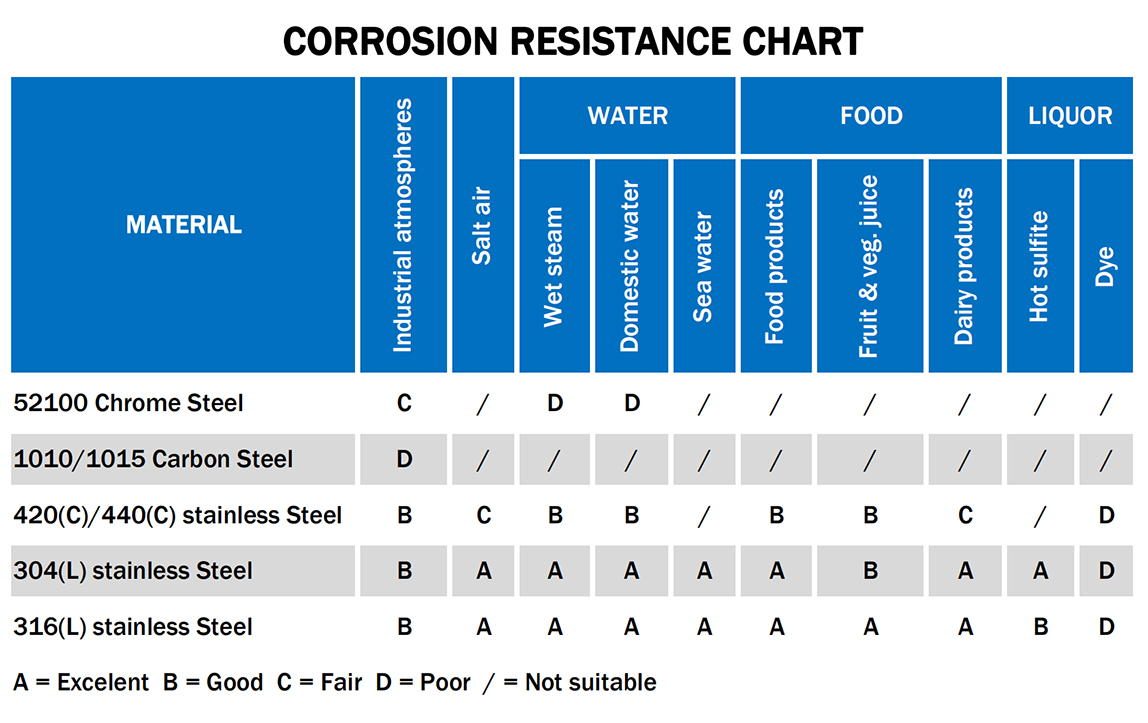

A: All produced balls are 100% sorted by the sorting bar and checked by the photoelectric surface defect detector. Before packaging samples balls from the lot are to send for final inspection to check for the roughness, roundness, hardness, variation, crush load and vibration in compliance with the standard. If all requirements are met, a inspection report will be made for the customer. Our sophisticated laboratory is equipped with high precision machines and equipment: Rockwell hardness tester, Vickers hardness tester, crushing load machine, roughness meter, roundness meter, diameter comparator, metallographic microscope, vibration measuring instrument, etc..

Q: Do you offer free samples for test?

A: Yes, we provide free samples to test and check quality.

Q: How long is your lead time?

A: Generally it takes around 3-5 days if the products are in stock. Or else the estimated lead time should be worked out according to your specific quantity, material and grade.

Q: We are not familiar with the international transportation. Will you handle all logistics?

A: Definitely, we deal with the logistic issues with our cooperated international freight forwarders with years’ of experience. The customers only need to provide us the basic information

Q: How is your packaging method?

A: 1. Conventional packaging method: 4 Inner boxes (14.5cm*9.5cm*8cm) per master carton (30cm*20cm*17cm) with dry plastic bag with VCI anti-rust paper or oiled plastic bag, 24 cartons per wooden pallet (80cm*60cm*65cm). Each carton weighs roughly 23kgs;

2.Steel drum packaging method: 4 steel drums (∅35cm*55cm) with dry plastic bag with VCI anti-rust paper or oiled plastic bag,4 drums per wooden pallet (74cm*74cm*55cm);

3.Customized packaging as per customer’s requirement.

Product detail pictures:

Related Product Guide:

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Trending Products Large Stainless Steel Sphere - Low noise high precision steel balls – Mingzhu , The product will supply to all over the world, such as: Canberra, Malta, Croatia, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

It is really lucky to meet such a good supplier, this is our satisfied cooperation, I think we will work again!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top