Wholesale Price China Steel Ball 50mm - 302 stainless steel balls high quality precision – Mingzhu

Wholesale Price China Steel Ball 50mm - 302 stainless steel balls high quality precision – Mingzhu Detail:

302 steel is a variation of classic 304; No magnetic and no tempered austenitic materials which has a remarkable corrosion resistance to organic chemical substances, oxidizing agents, food products and sterilizing solutions, but the resistance against sulfuric acids is low.

Specification

|

302 stainless steel balls |

|

|

Diameters |

2.0mm – 55.0mm |

|

Grade |

G100-G1000 |

|

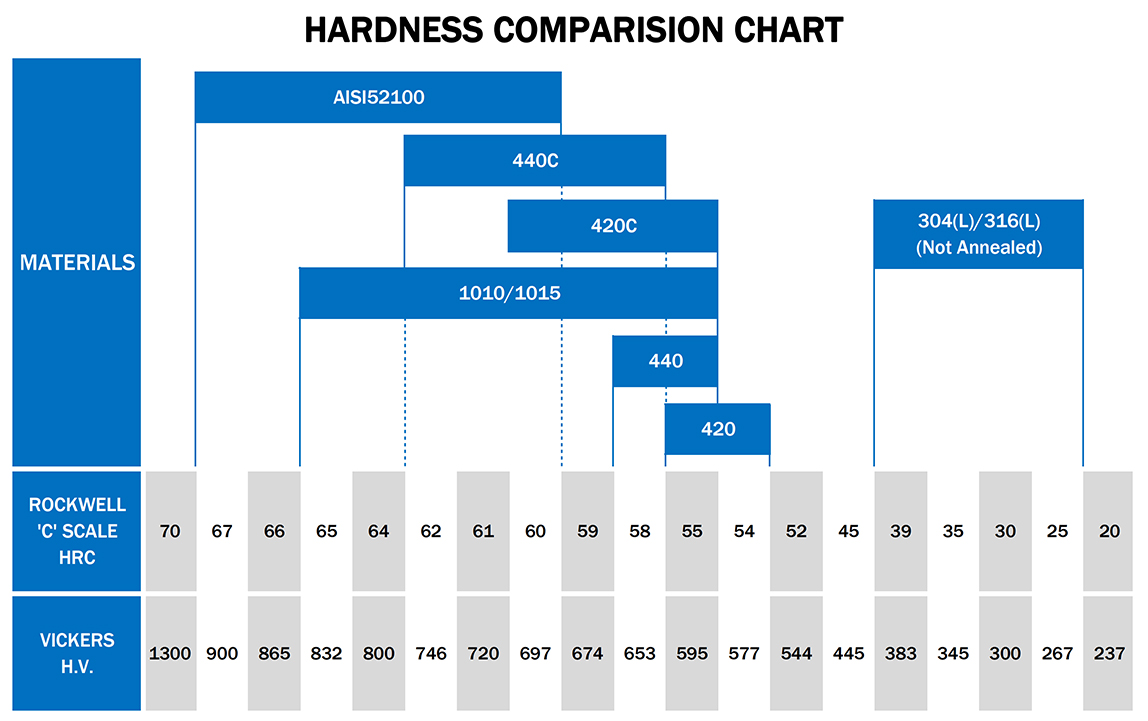

Hardness |

25/39HRC |

|

Application |

aerosol and dispenser sprayers, garden and home sprinklers, miniature pumps, medical application valves, perfume atomizer micro pumps, agricultural backpack sprayers. |

Equivalence Of Material

|

302 stainless steel balls |

|

|

AISI/ASTM(USA) |

302 |

|

VDEh (GER) |

1.4300 |

|

JIS (JAP) |

SUS302 |

|

BS (UK) |

302 S 25 |

|

NF (France) |

Z10CN18-09 |

|

ГОСТ(Russia) |

12Х18Н9 |

|

GB (China) |

1Cr18Ni9 |

Chemical Composition

|

302 stainless steel balls |

|

|

C |

≤0.15% |

|

Si |

≤1.00% |

|

Mn |

≤2.00% |

|

P |

≤0.035% |

|

S |

≤0.03% |

|

Cr |

17.00% - 19.00% |

|

Ni |

8.00% - 10.50% |

Our Advantage

● We have been engaged in steel ball production for more than 26 years;

● We offer a great variety of sizes ranged from 3.175mm to 38.1mm. Non-standard sizes and gauges can be manufactured under special request (such as 5.1mm, 5.15mm, 5.2mm, 5.3mm 5.4mm for seat track; 14.0mm for cam shaft and CV joint, etc.);

● We have a wide stock availability. Most of the standard sizes (3.175mm~38.1mm) and gauges (-8~+8) are available, which can be delivered immediately;

● Each batch of balls is inspected by sophisticated machines: roundness tester, roughness tester, metallographic analysis microscope, hardness tester (HRC and HV) to guarantee the quality.

FAQ

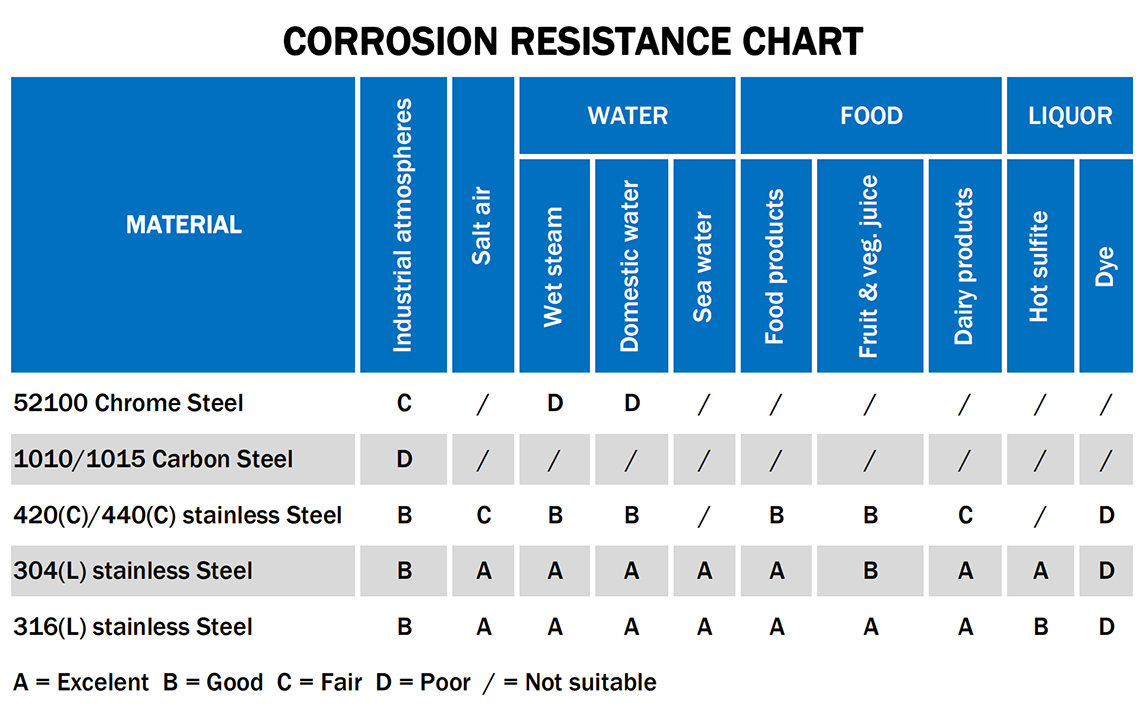

Q:What are the main differences between 300 and 400 series stainless steel balls?

A: To choose the proper steel brand for stainless steel balls, we should get to know well the properties of each brand and the application of the balls. The most common used stainless steel balls can be divided simply in two groups: 300 series and 400 series.

300 series “austenitic” stainless steel balls contain more chromium and nickel elements and are theoretically non-magnetic (actually are very low-magnetic. Totally non-magnetic require additionally heat treated.). Normally they are produced without the heat treatment process. They have better corrosion resistance than 400 series (in fact, the highest corrosion resistance of the stainless group. Although 300 series balls are all quite resistant, however 316 and 304 balls show different resistance to some substance. For more details, please refer to pages of different stainless steel balls) . They are less brittle, so can be applied also for sealing use. 400 series stainless steel balls contain more carbon, which makes it magnetic and more hardness. They can be easily heat treated like chrome steel balls or carbon steel balls to increase hardness. 400 series stainless steel balls are commonly used for applications that demand water-resistance, strength, hardness and wear resistance.

Q: What kind of certificates do you achieve?

A: We own ISO9001:2008 management system certification and IATF16949: 2016 automotive industry quality management system certification.

Q: We are not familiar with the international transportation. Will you handle all logistics?

A: Definitely, we deal with the logistic issues with our cooperated international freight forwarders with years’ of experience. The customers only need to provide us the basic information

Q: How is your packaging method?

A: 1. Conventional packaging method: 4 Inner boxes (14.5cm*9.5cm*8cm) per master carton (30cm*20cm*17cm) with dry plastic bag with VCI anti-rust paper or oiled plastic bag, 24 cartons per wooden pallet (80cm*60cm*65cm). Each carton weighs roughly 23kgs;

2.Steel drum packaging method: 4 steel drums (∅35cm*55cm) with dry plastic bag with VCI anti-rust paper or oiled plastic bag,4 drums per wooden pallet (74cm*74cm*55cm);

3.Customized packaging as per customer’s requirement.

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for Wholesale Price China Steel Ball 50mm - 302 stainless steel balls high quality precision – Mingzhu , The product will supply to all over the world, such as: Rwanda, Ukraine, Curacao, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top